With high price volatility in the energy sector the search for more energy efficient products will surely continue.

Thanks to the new punker diffuser technology, punker fan wheels achieve high degrees of efficiency resulting in higher power density and lower noise transmission.

punker Diffuser Technology

Range of Applications

punker fan wheels wheels have been designed for un-housed plenum- / plug-fans used in HVAC, Car Wash, Industrial and Agricultural applications to achieve a high degree of efficiency resulting in higher power density and lower noise transmission.

- HVAC applications

- Air Handling Units (AHU)

- Building ventilation systems

- Data Center Cooling

- Supply / exhaust air in Hyper Scale Data Centers

- Cooling of compressors

- Grain dryers and silo ventilation

How it works

- One unique characteristic of the punker fan wheels is the so called radial diffuser. The diameters of the front- and backplate are larger than the outer blade diameter (see the red marked “diffuser area” in the picture below).

- In terms of ventilation engineering, the diffuser acts as a converter. It transforms the kinetic energy of the air flow into pressure energy with the result of efficiency improvement and noise reduction. The same effect is usually achieved in fan scroll housings by means of a discharge evase.

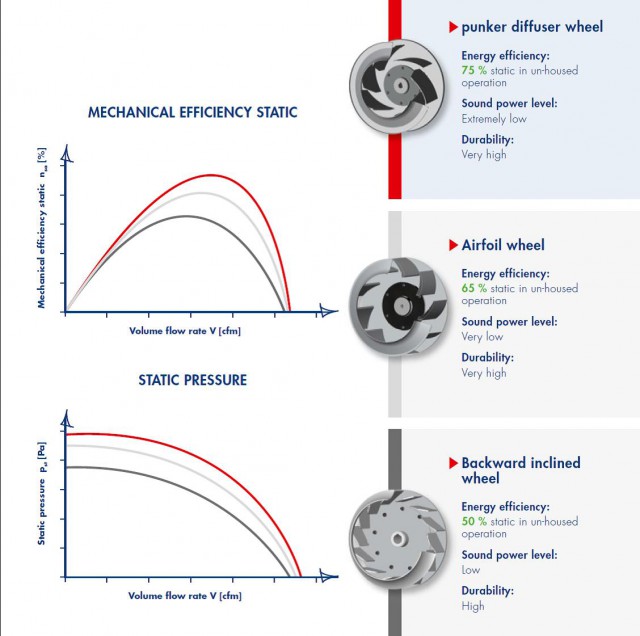

- The punker diffuser design offers increased efficiency over competitor’s airfoil / backward inclined blade designs.

Advantages over other wheel designs

-

-

- the impeller draws in air via the inlet cone and transports it outwards radially

- the velocity of the air is highest at the fan inlet

- due to an increased cross-section, the velocity of the air is being reduced towards the discharge

- the air keeps slowing down further after passing the blades

- dynamic pressure is being converted into static pressure, resulting in an increased output of usable energy

- power input and torque are kept constant. Thus, increased usable energy leads to a higher efficiency compared to common wheel designs

-

The punker diffuser design offers increased efficiency over competitors’ airfoil or backward inclined blade designs. It reduces cost by consuming less power, therefore requiring a smaller and cheaper motor.

The punker diffuser wheel delivers up to 75% static efficiency (83% total efficiency) in un-housed operation while maintaining extremely low sound power levels and a very high durability.